Innovations for greener business model

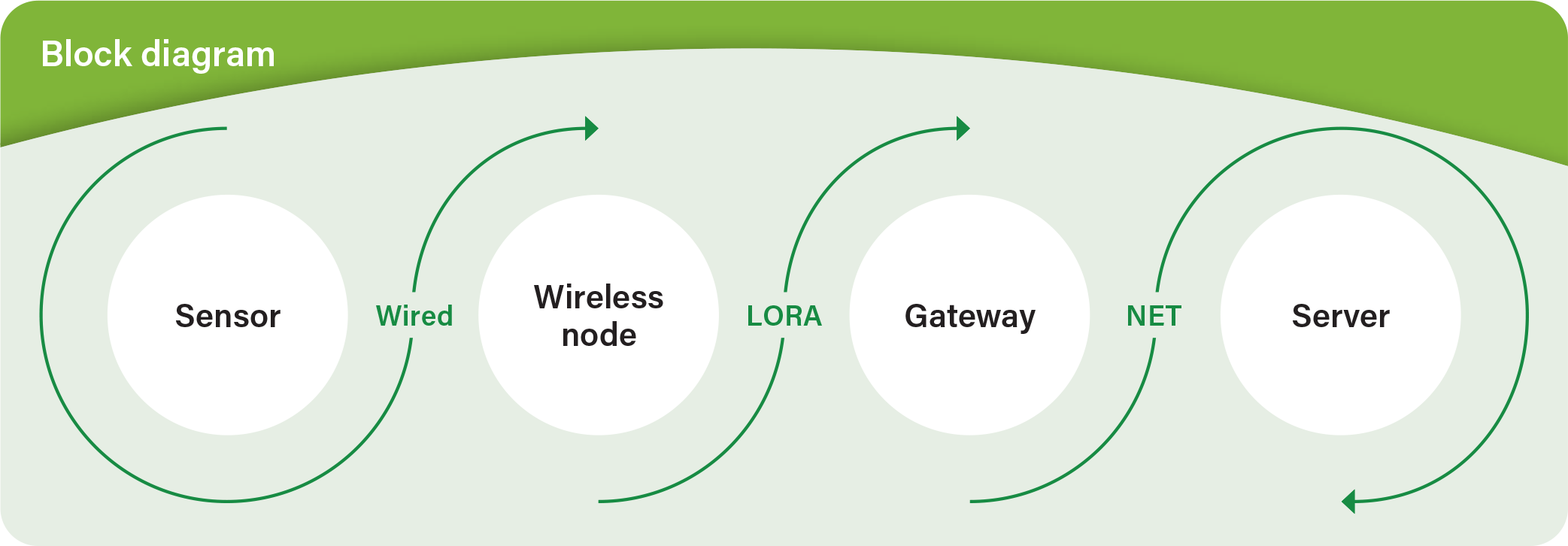

We believe that the metals & mining sector has a significant role to play in the transition to a low-carbon future and the emergence of a green economy. Constant innovation and adoption of technologies that improve our operational and energy efficiency and reduce our carbon footprint together with the embedding of circularity in our processes are helping us deliver on our commitment.

Key material issues

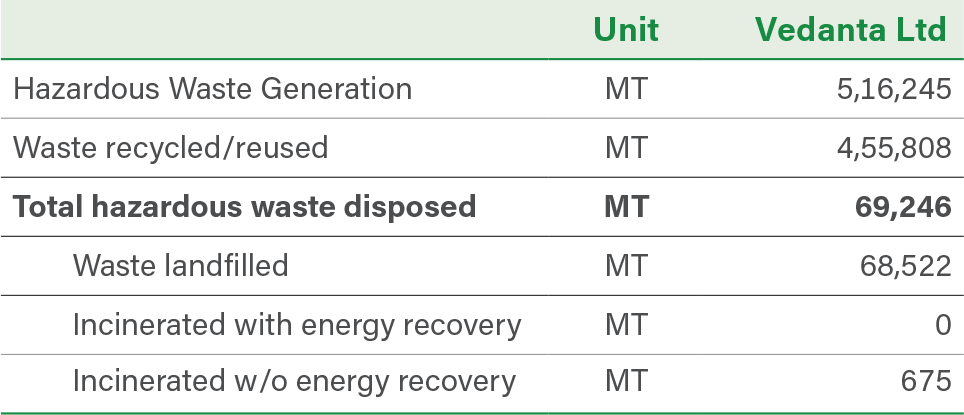

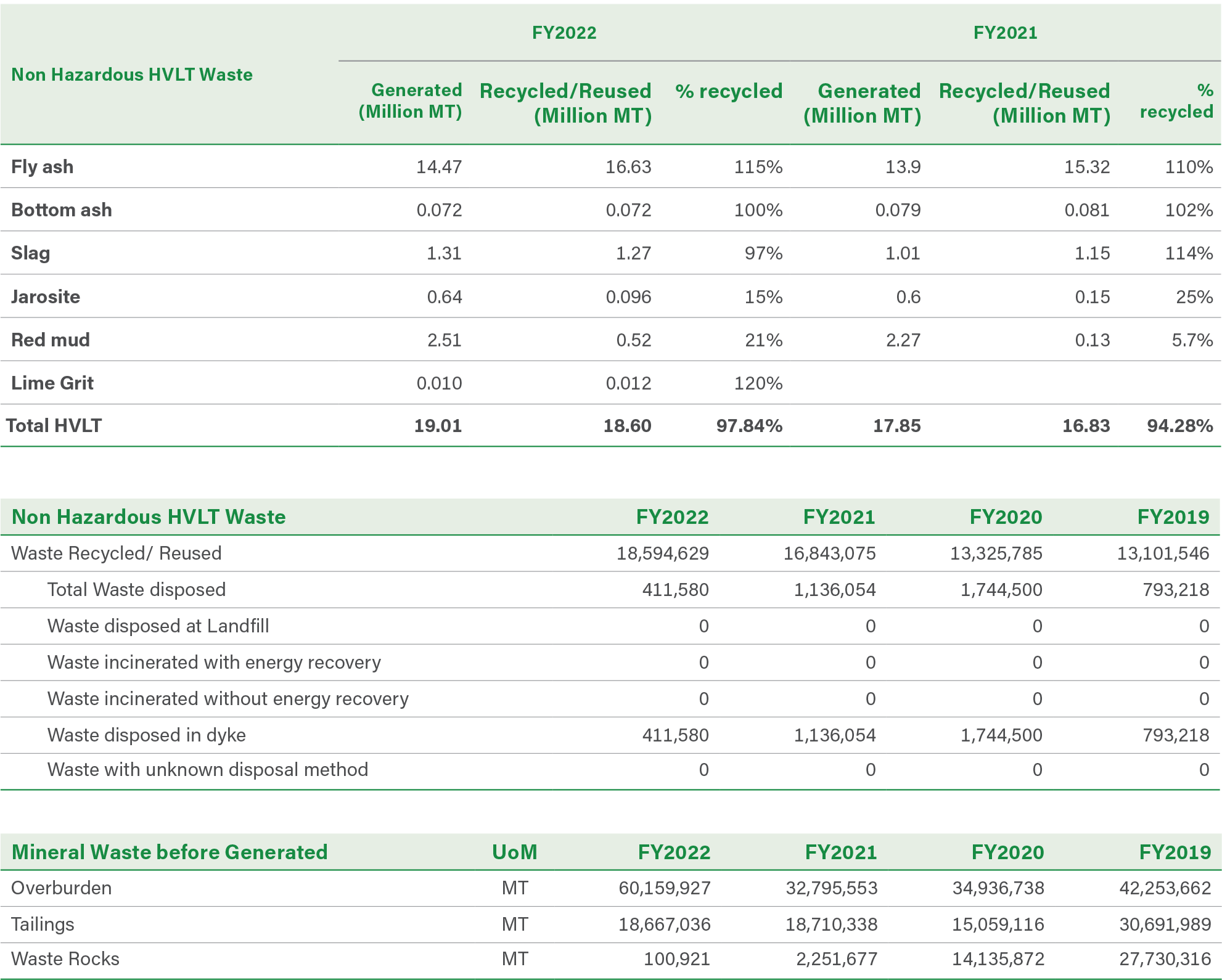

Solid waste management

Tailings management

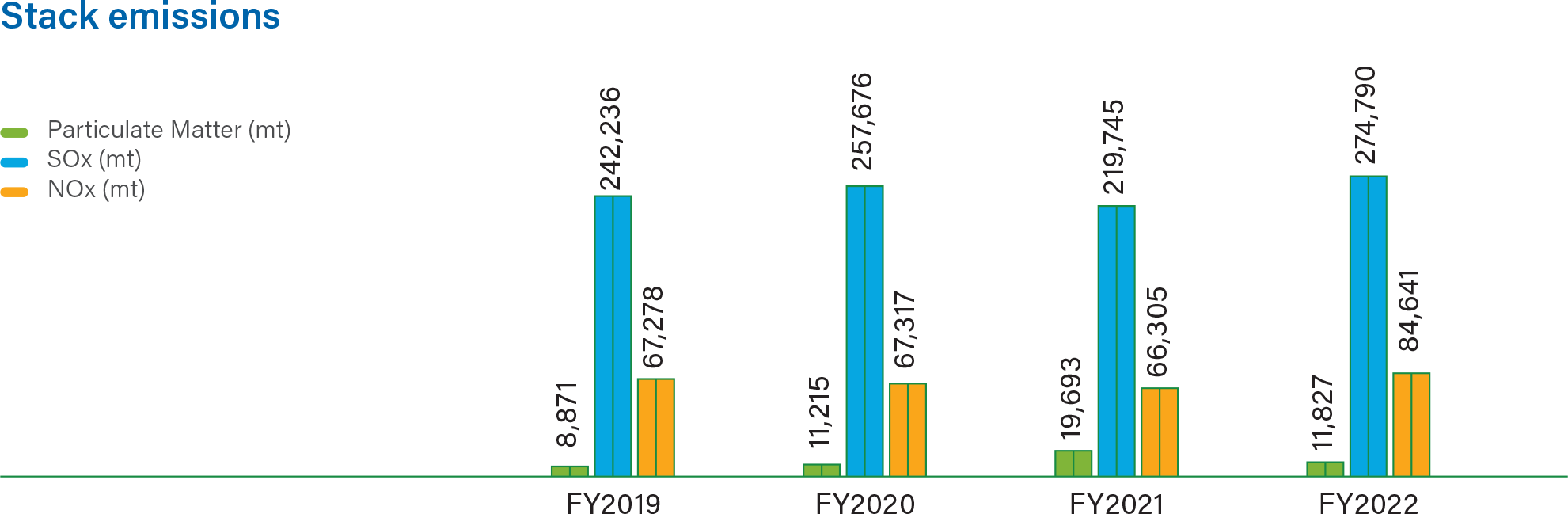

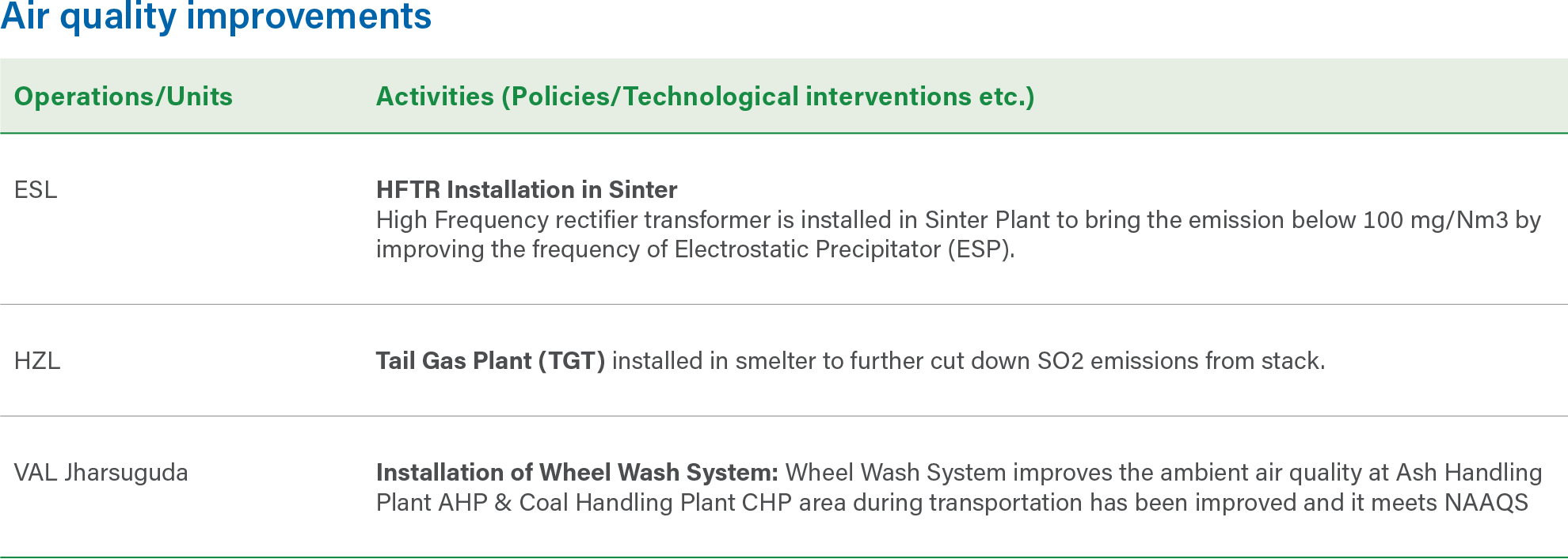

Air quality and emissions management

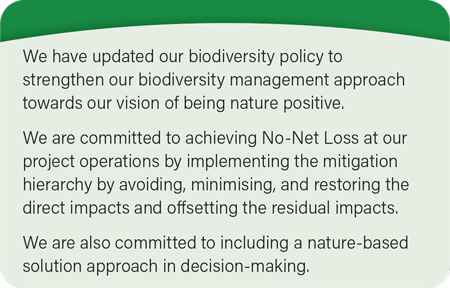

Biodiversity

SDGs impacted

Sub-goals

12.5: By 2030, substantially reduce waste generation through prevention, reduction, recycling and reuse

15.1: By 2020, ensure the conservation, restoration and sustainable use of terrestrial and inland freshwater ecosystems and their services, in particular forests, wetlands, mountains and drylands, in line with obligations under international agreements

15.2: By 2020, promote the implementation of sustainable management of all types of forests, halt deforestation, restore degraded forests and substantially increase afforestation and reforestation globally

15.9: By 2020, integrate ecosystem and biodiversity values into national and local planning, development processes, poverty reduction strategies and accounts