Achieving net water positivity by 2030

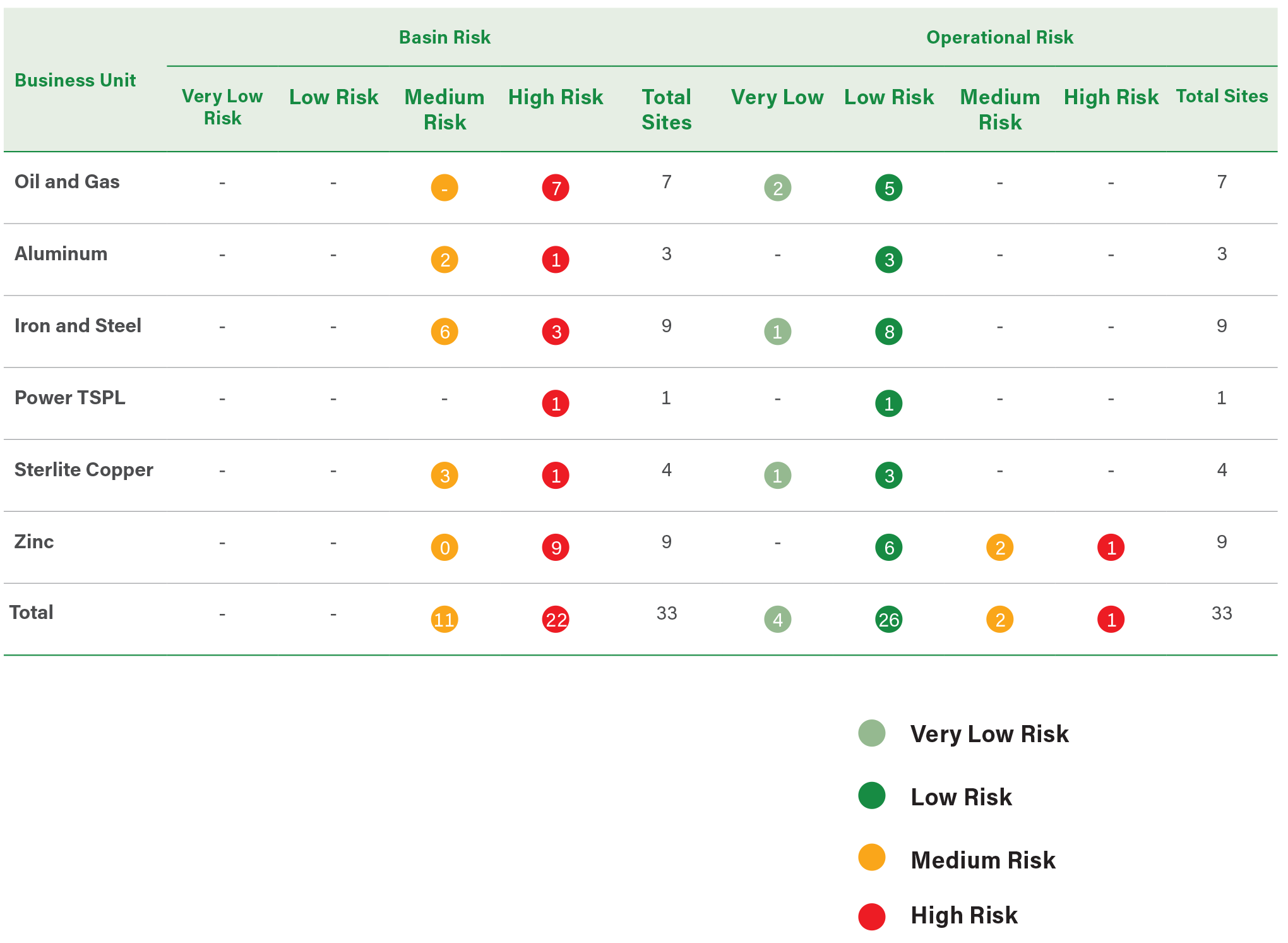

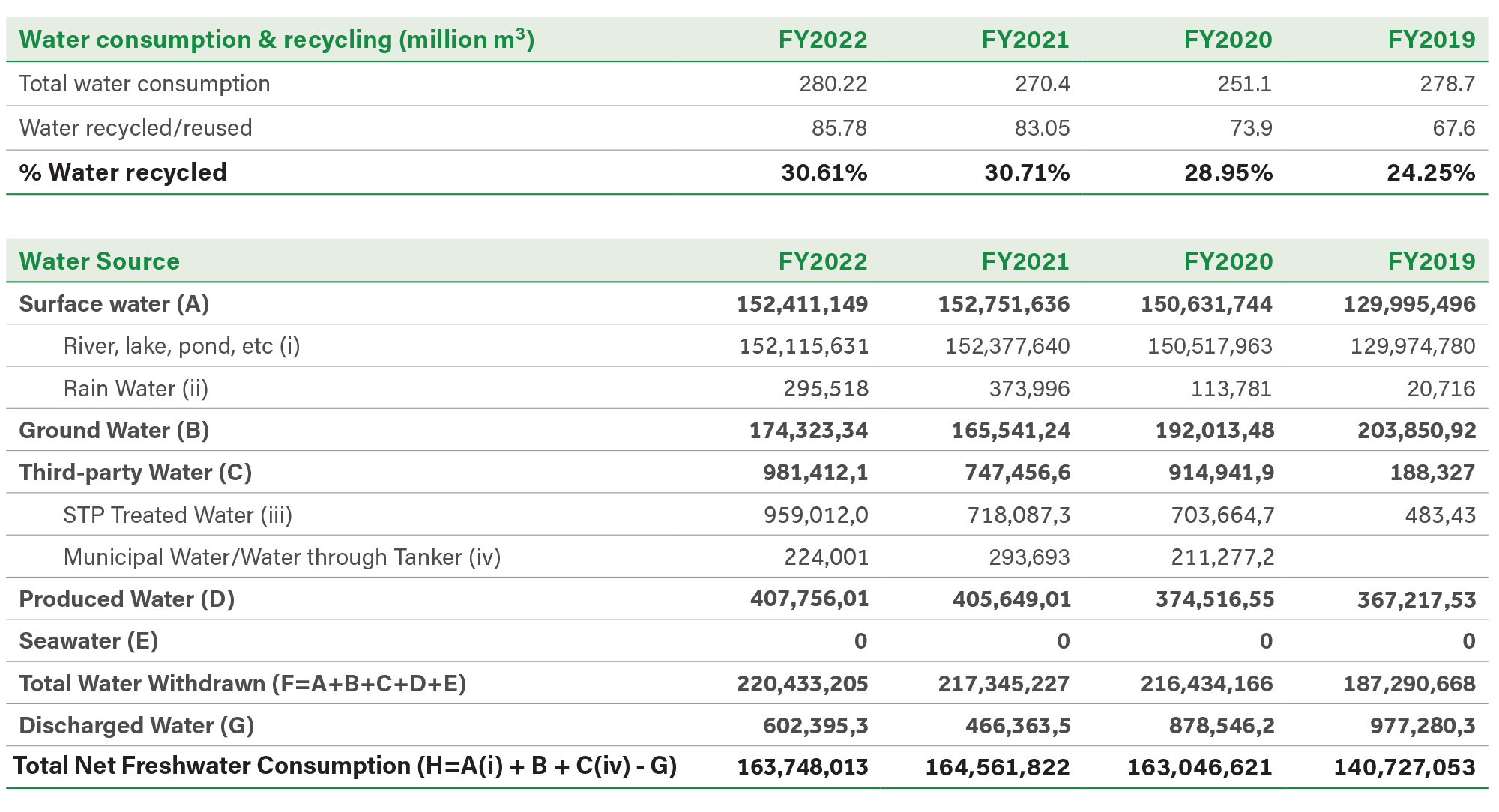

Water has been identified as a societal risk, with access to clean water emerging as one of the most critical issues affecting economic activity across the world. With many of our operations in water-stressed areas, we maintain sustained focus on efficient water use, and giving back more water to the environment than we take. Not only are we exploring less water-intensive technologies and embedding circularity in our water management, but also ensuring water security in areas where we operate by replenishing water in watersheds and other community sources.

Key material issues

Water security

SDGs impacted

Sub-goals6.3: By 2030, improve water quality by reducing pollution, eliminating dumping and minimising release of hazardous chemicals and materials, halving the proportion of untreated wastewater and substantially increasing recycling and safe reuse globally

6.4: By 2030, substantially increase water-use efficiency across all sectors and ensure sustainable withdrawals and supply of freshwater to address water scarcity and substantially reduce the number of people suffering from water scarcity

6.5: By 2030, implement integrated water resources management at all levels, including through transboundary cooperation as appropriate

6.6: Support and strengthen the participation of local communities in improving water and sanitation management