Net Zero Carbon by 2050 or sooner

Climate change poses a grave risk to society, and it is the responsibility of all global actors to commit to decarbonise themselves at an urgent pace. We support the Paris Agreement to limit long-term global average temperature rise to well below 2oC and to pursue efforts to limit warming to 1.5oC. We welcome the Government of India’s decision to make India a net zero carbon economy by 2070.

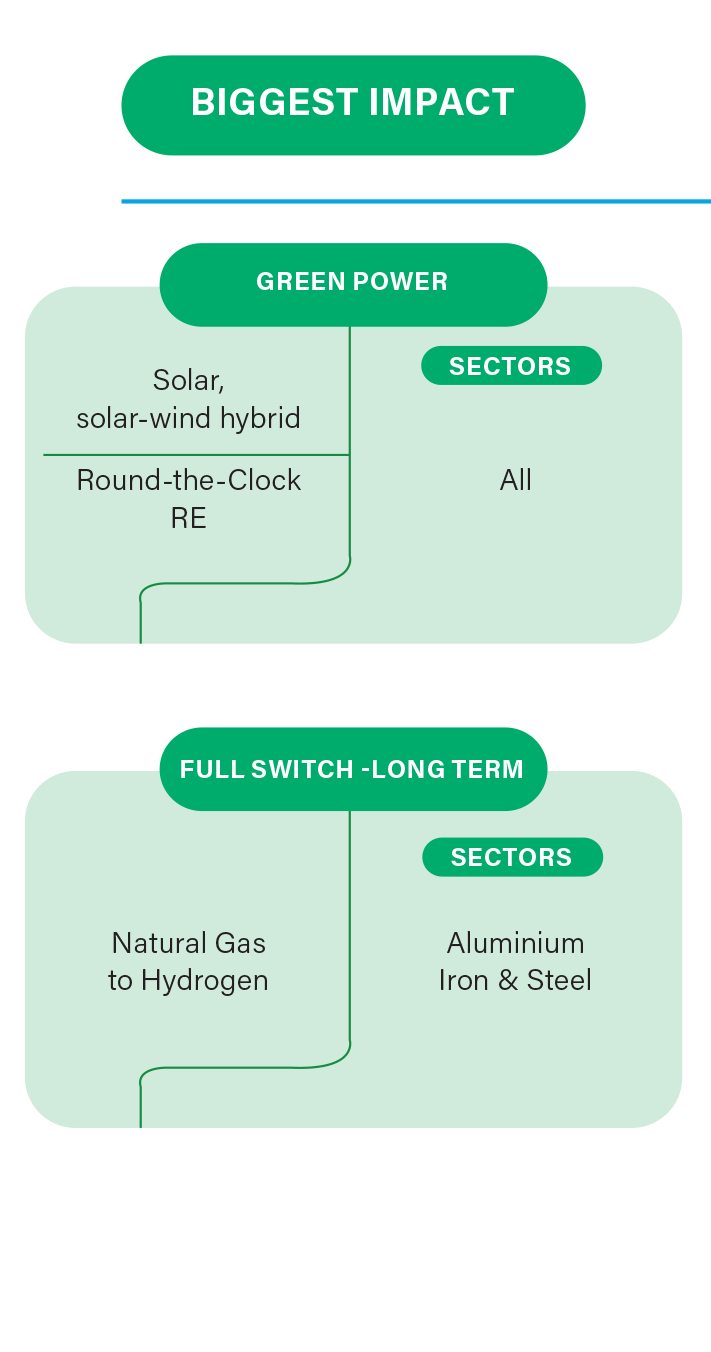

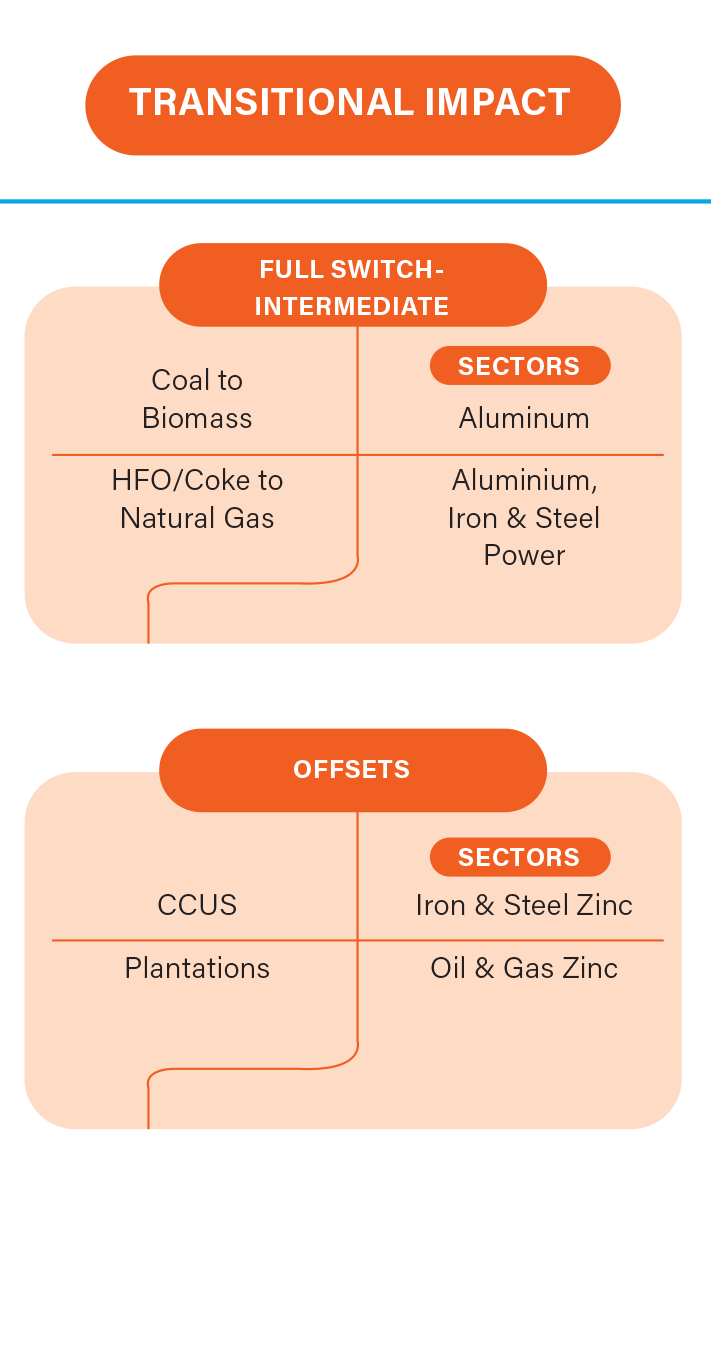

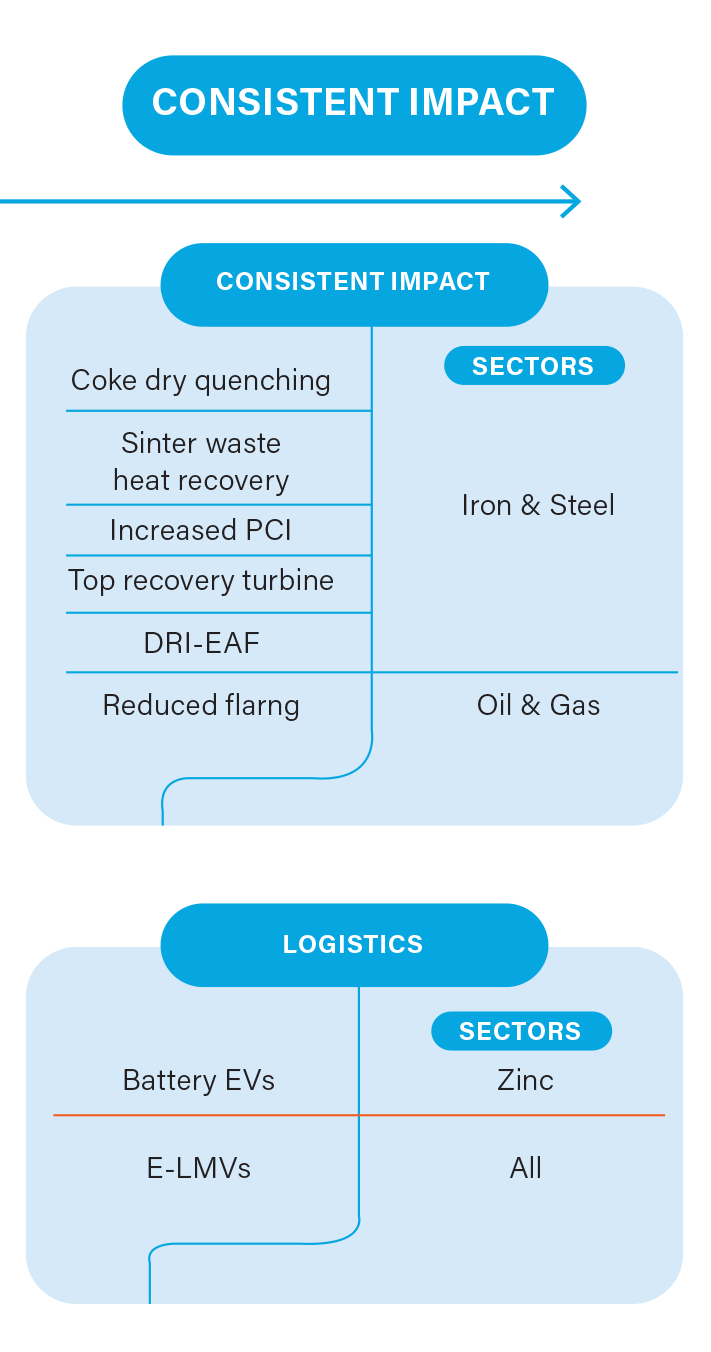

We have set ourselves carbon reduction targets that are in alignment with these national and international goals. Through a well-considered strategy to improve our energy and process efficiency together with a diversification of our energy mix across all operations, we intend to meet our goal of Net Zero Carbon by 2050 or sooner.

Key material issues

Climate change and decarbonisation

SDGs impacted

Sub-goals7.2: By 2030, increase substantially the share of renewable energy in

the global energy mix

12.2: By 2030, achieve the sustainable management and efficient use

of natural resources

13.2: Integrate climate change measures into national policies,

strategies and planning